戴升 教授 博士生导师

电子邮箱:shengdai@ecust.edu.cn

个人主页:http://shengdai.ecust.edu.cn

办公地址:上海市徐汇区梅陇路130号 华东理工大学 五教205

招生方向:应用化学(硕士,博士)、材料科学与工程(硕士),材料与化工(工程硕士)

教育背景:

2005.09—2009.07 清华大学 材料科学与工程系 学士

2009.09—2014.07 清华大学 材料科学与工程系 博士 (导师:朱静 院士)

工作经历:

2014.11—2016.06 密歇根大学 材料科学与工程系 博士后 (合作导师:Xiaoqing Pan教授)

2016.07—2019.03 加州大学尔湾分校 材料与化工系 博士后 (合作导师:Xiaoqing Pan教授)

2019.04—2021.08 华东理工大学 化学与分子工程学院 特聘研究员

2021.09 至今 华东理工大学 化学与分子工程学院 教授

研究概况:

戴升教授课题组(ISTEM Group)致力于先进催化剂精准结构与构效关系的研究。运用先进电子显微镜表征技术,在原子尺度探究环境与能源催化剂的结构特征与动态演化规律,解析催化剂活性位点与反应机理,明确构效关系。课题组的主要研究方向包括:

1. 反应进程中催化剂动态过程的原子尺度研究(热催化、电催化动态过程)。

2. 电子束敏感催化剂(分子筛、COF/MOF基,等)的精准结构解析。

3. 先进能源催化剂(HER、ORR、OER、CO2RR等)的设计合成与构效关系研究。

4. 多场耦合原位电镜设备与技术的研发。

戴升教授目前已发表SCI论文150余篇;以第一/通讯作者(共同)身份发表50余篇,包括Nat. Mater., Nat. Catal., Nat. Commun., , J. Am. Chem. Soc., Adv. Mater., PNAS, Chem, Nano Lett.等。作为负责人主持国家海外高层次人才项目、国家自然科学基金面上项目、上海市高校特聘教授、上海市海外高层次人才计划、上海市“青年科技启明星”计划、上海市自然科学基金,及多项企业联合科研项目。

戴升教授课题组依托华东理工大学“费林加诺贝尔奖科学家联合研究中心”,拥有国际领先的双球差透射电镜、环境透射电镜及多种原位电镜设备。欢迎应用化学、材料科学与工程、工业催化等方向的研究生加入本课题组;同时欢迎化学、化工、材料等专业的本科生来课题组交流学习。课题组长期招聘电子显微学方向的博士后。

主要获奖:

1. 上海市青年五四奖章(个人),2023年

2. 上海市优秀科普作品《118化学元素》 (戴升,张馨予 著),2023年

3. 北京市优秀毕业生,2014年

4. 清华大学优秀博士论文,2014年

5. 教育部博士研究生学术新人奖,2012年

课程教学:

1. 物理化学实验(本科生)

2. 分析化学实验(本科生)

3. 催化剂表征 Characterization of Catalysts (研究生,英文课程)

社会兼职:

1. Chinese Journal of Chemistry期刊青年编委

2. 上海市科普作家协会会员

3. 上海技术交易所智库专家

近三年代表论文(通讯作者):

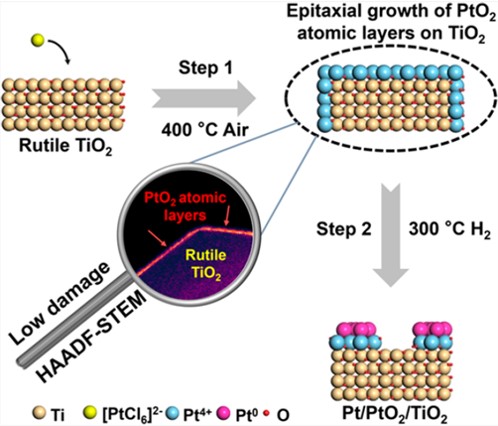

1. Xuan Tang#, Anwen Yu#, Qianqian Yang#, Haiyang Yuan, Zhaohua Wang, Junzhong Xie, Lihui Zhou, Yun Guo*, Ding Ma*, Sheng Dai*. Significance of epitaxial growth of PtO2 on rutile TiO2 for Pt/TiO2 catalysts. J. Am. Chem. Soc. 2024, 146, 3764−3772.

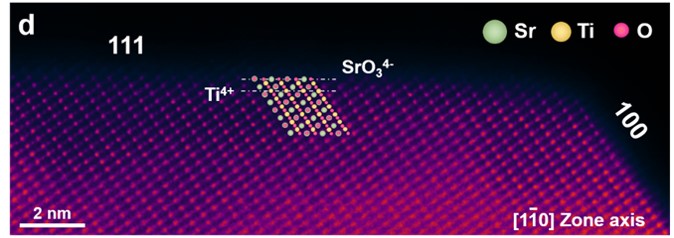

2. Yang Zhang, Xuefeng Wu, Zhi-Hao Wang, Yu Peng, Yuanwei Liu, Shuang Yang, Chenghua Sun, Xiaoxiang Xu, Xie Zhang, Jun Kang, Su-Huai Wei, Peng Fei Liu*, Sheng Dai*, Hua Gui Yang*. Crystal facet engineering on SrTiO3 enhances photocatalytic overall water splitting. J. Am. Chem. Soc. 2024,146, 10, 6618–6627.

3. Gonglei Shao#,*, Changfei Jing#, Zhinan Ma, Yuanyuan Li, Weiqi Dang, Dong Guo, ManmanWu, Song Liu, Xu Zhang, Kun He, Yifei Yuan, Jun Luo, Sheng Dai*, Jie Xu*, Zhen Zhou*. Nat. Commun. 2024, 15, 385.

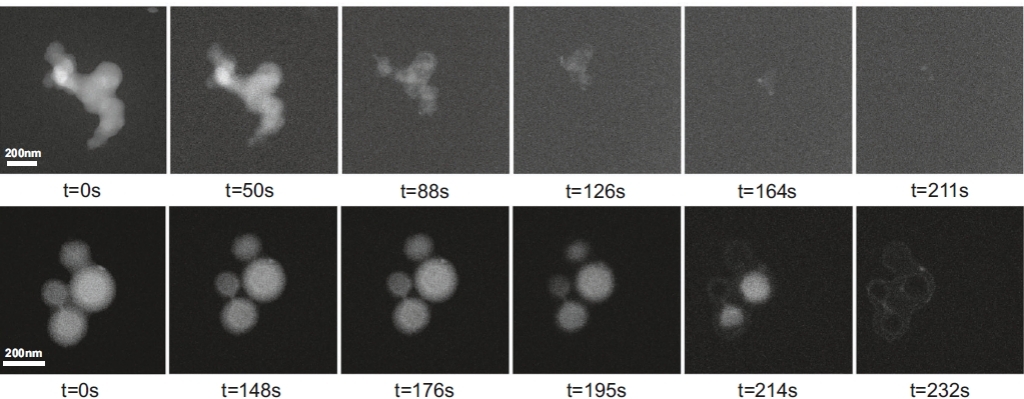

4. Ming Gao, Yongjun Jang, Lu Ding*, Yunfei Gao, Sheng Dai*, Zhenghua Dai, Guangsuo Yu, Wenming Yang*, FuchenWang*. Mechanism of the noncatalytic oxidation of soot using in situ transmission electron microscopy. Nat. Commun. 2023, 14, 6526.

5. Ji Wei Sun#, XuefengWu#, Peng Fei Liu*, Jiacheng Chen, Yuanwei Liu, Zhen Xin Lou, Jia Yue Zhao, Hai Yang Yuan, Aiping Chen, Xue Lu Wang, Minghui Zhu, Sheng Dai*, Hua Gui Yang*. Scalable synthesis of coordinatively unsaturated metal-nitrogen sites for large-scale CO2 electrolysis. Nat. Commun. 2023, 14, 1599.

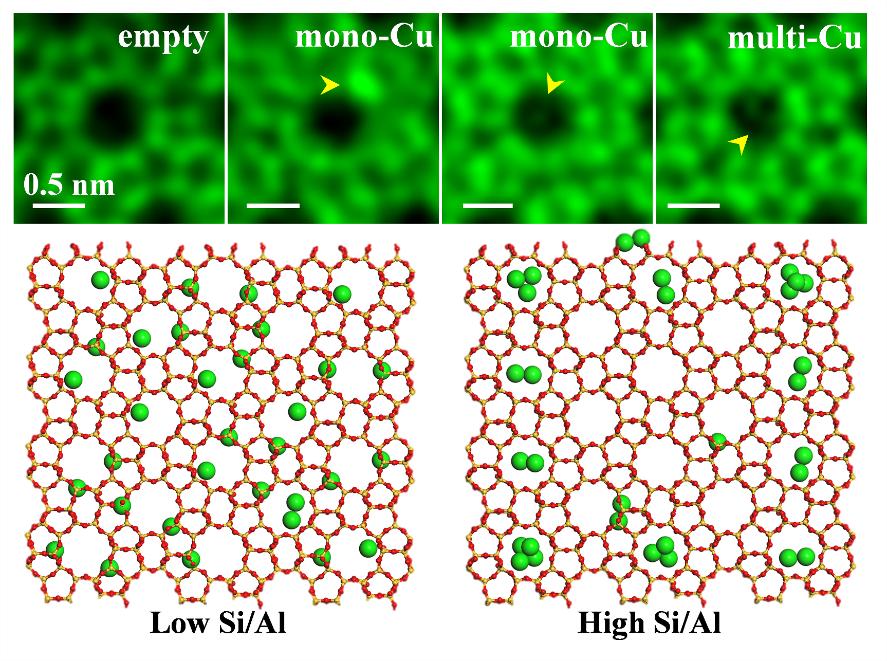

6. Xuan Tang#, Jiajie Ye#, Lisheng Guo, Tiancheng Pu, Lu Cheng, Xiao-Ming Cao, Yanglong Guo, Li Wang, Yun Guo, Wangcheng Zhan*, Sheng Dai*. Atomic Insights into the Cu Species Supported on Zeolite for Direct Oxidation of Methane to Methanol via Low-Damage HAADF-STEM. Adv. Mater. 2023, 2208504.

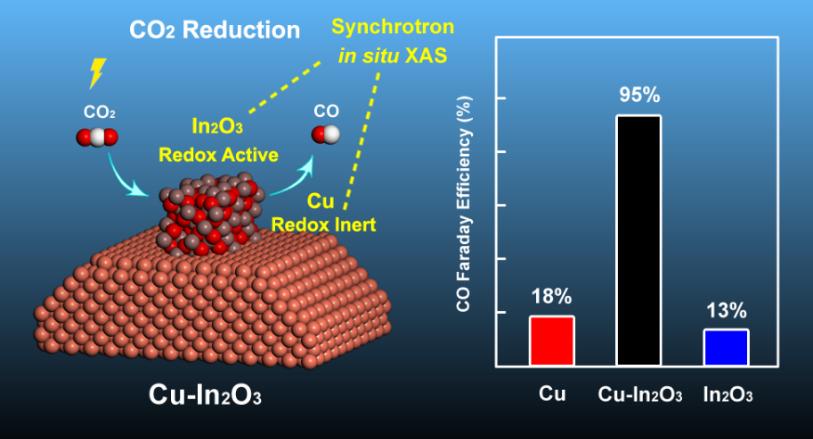

7. Yanyan Jia, Hua-Shan Hsu, Wan-Chun Huang, Da-Wei Lee, Sheng-Wei Lee, Tsan-Yao Chen, Lihui Zhou, Jeng-Han Wang*, Kuan-Wen Wang*, Sheng Dai*. Probing the Roles of Indium Oxides on Copper Catalysts for Enhanced Selectivity during CO2‑to-CO Electrochemical Reduction. Nano Lett. 2023, 23, 2262−2268.

8. Wenwen Xu#, Tengfei Ma#, Haocheng Chen, Dianhui Pan, Zhongfeng Wang, Sixie Zhang, Ping Zhang, Shanjun Bao, Qihao Yang, Lihui Zhou, Ziqi Tian*, Sheng Dai*, Zhiyi Lu*. Scalable Fabrication of Cu2S@NiS@Ni/NiMo Hybrid Cathode for High-Performance Seawater Electrolysis. Adv. Funct. Mater. 2023, 2302263.

9. Jie Xu#, Gonglei Shao#, Xuan Tang#, Fang Lv, Haiyan Xiang, Changfei Jing, Song Liu*, Sheng Dai*, Yanguang Li*, Jun Luo*, Zhen Zhou. Frenkel-defected monolayer MoS2 catalysts for efficient hydrogen evolution. Nat. Commun.2022, 13, 2193.

10. Zhaohua Wang#, Chunyang Dong#, Xuan Tang#, Xuetao Qin, Xingwu Liu, Mi Peng, Yao Xu, Chuqiao Song, Jie Zhang, Xuan Liang, Sheng Dai*, Ding Ma*.CO-tolerant RuNi/TiO2 catalyst for the storage and purification of crude hydrogen. Nat. Commun.2022, 13, 4404.

11. Jie Xu#, Heng Xu#, Anqi Dong#, Hao Zhang,* Yitong Zhou, Hao Dong, Bo Tang, Yifei Liu, Lexi Zhang, Xijun Liu, Jun Luo, Lijian Bie, Sheng Dai*, Yuhang Wang*, Xuhui Sun, Yanguang Li*. Strong electronic metal–support interaction between Iridium single atoms and a WO3 support promotes highly efficient and robust CO2 cycloaddition. Adv. Mater. 2022, 2206991.

12. Dongsheng Xia, Xuan Tang, Sheng Dai*, Rile Ge, Alexander Rykov, Junhu Wang, Tzu-Hsi Huang, Kuan-Wen Wang, Yinping Wei, Kai Zhang, Jia Li, Lin Gan*, Feiyu Kang*. Ultrastable Fe–N–C fuel cell electrocatalysts by eliminating non-coordinating nitrogen and regulating coordination structures at high temperatures. Adv. Mater. 2022, 2204474.

13. Chenyuan Zhu#, Lihui Zhou#, Zhibin Zhang#, Chunlei Yang, Guoshuai Shi, Siwen Zhao, Huoliang Gu, Jing Wu, Xinyang Gao, Yefei Li, Kaihui Liu*, Sheng Dai*, Liming Zhang*. Dynamic restructuring of epitaxial Au–Cu biphasic interface for tandem CO2-to-C2+ alcohols conversion. Chem 2022, 8, 1–14.

14. Yanyan Jia, Tzu-Hsi Huang, Shuan Lin, Lisheng Guo, Yu-Min Yu, Jeng-Han Wang, Kuan-Wen Wang*, Sheng Dai*. Stable Pd−Cu Hydride Catalyst for Efficient Hydrogen Evolution. Nano Lett. 2022, 22, 1391−1397.

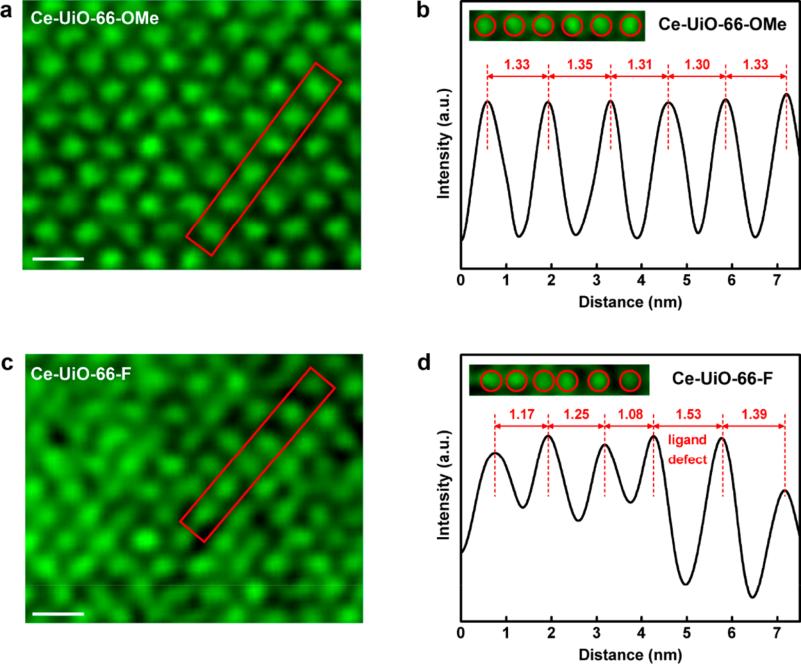

15. Qihao Yang#, Yinming Wang#, Xuan Tang#, Qiuju Zhang, Sheng Dai*, Huaitao Peng, Yichao Lin, Ziqi Tian, Zhiyi Lu*, Liang Chen*. Ligand Defect Density Regulation in Metal−Organic Frameworks by Functional Group Engineering on Linkers. Nano Lett. 2022, 22, 838−845.